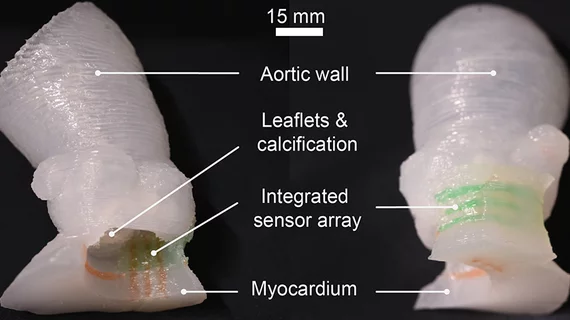

3D-printed heart valve models have the feel and look of the real thing

Researchers have developed a new process for 3D printing lifelike models of a patient’s aortic valve, sharing their findings in Science Advances.

The patient-specific models were designed specifically to help clinicians prepare for transcatheter aortic valve replacement (TAVR) procedures.

“Our goal with these 3D-printed models is to reduce medical risks and complications by providing patient-specific tools to help doctors understand the exact anatomical structure and mechanical properties of the specific patient’s heart,” senior researcher Michael McAlpine, a professor at the University of Minnesota, said in a prepared statement. “Physicians can test and try the valve implants before the actual procedure. The models can also help patients better understand their own anatomy and the procedure itself.”

CT scans of the patient are used to make the aortic root models, and then those scans are 3D printed using the researchers’ 3D printing technology. The inks used by 3D printers are typically nothing like actual heart tissue—they are much more rigid—but the University of Minnesota’s Visible Heart Laboratories was able to provide McAlpine et al. with special silicone-based inks.

In the statement, McAlpine noted that he thinks this is just the beginning for this significant development.

“As our 3D-printing techniques continue to improve and we discover new ways to integrate electronics to mimic organ function, the models themselves may be used as artificial replacement organs,” he said. “Someday maybe these ‘bionic’ organs can be as good as or better than their biological counterparts.”

Funding for the team’s work was provided by Medtronic, the National Institutes of Health and others. Medtronic representatives also contributed to the actual research itself.

The full Science Advances analysis is available here.